The Underwood 5 typewriter has the serial number stamped on the frame-top near the right spool. The number itself is generally followed by a type-designation, so the pattern is xxxxxx-5 for a regular Nr. 5. The number is on a flat, machined surface and linear - feasible to stamp with an automatic numbering stamp.

Here the Underwood 5 serial number on a 1920 machine (type "5" on the extra face/facet):

Probably on every Underwood 5 (or 4, 3, 46T etc.) there is another number stamped into the frame. This number is stamped in the flat, machined surface under the front left foot. The digits are arranged around the screw-hole for the foot, to fit in the area. This makes it less likely to have been an automatically incrementing numbering stamp, but more likely hand-stamped.

Here the extra "front left foot number" on that same 1920 machine:

Another example; here the front-left foot and the top-right of the frame in one picture:

(Yes, it's in pieces. This Underwood was completely broken; dropped/tumbled onto a concrete floor from some height. The cast iron frame was shattered and all panels crumpled. The wreck is being salvaged for parts to fix other machines.)

From these and a few other machines, e.g. on The Database or mentioned on the net, some serial numbers with their front left foot numbers can be found.

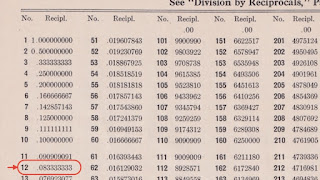

serial number year front left foot number

475,051 1912 541,824

734,809 1914 874,286

1,411,885 1920 1,812,200

1,872,237 1924 2,461,255

2,446,801 1928 389,092

3,677,613 1930 111,938 (46T)

Can't help but wonder; what are these numbers?

They don't look to contain dates. They do not correlate with the machine serial numbers. Come to that; are they actually serialised, another serial number range for the foundry? They are not all incrementing.

Are they perhaps job-numbers; per order of a batch of finished-frames so that several machines within a range of serial numbers will have the same front left foot number?

Could the "24" on that 1924 machine be a year prefix to a job-number? But that wouldn't explain the "18" on the 1920 machine (late 1920, November-ish).

Update!:

If the last two numbers are ignored, the range is actually nicely incrementing. That could be reasoned e.g. when the '28 and '30 numbers are after a change in the method. (E.g. restart at zero every year), after the number started to become cumbersome to stamp in the mid 1920s. Then the serial and left foot numbers correlate very well - they have a linear relation:

Left foot numbers rise 1.38 times the speed of serials. That could indicate that not all casting numbers are for machine frames - about 73% of stamped parts would be for Underwood 5 typewriter frames. The practice of stamping the casings would have started around Underwood 5 machine serial number 100,000 - about 1906. (Could be checked, will a pre-1906 machine have a front left foot number?)

Could be that for the Underwood 5 the left foot numbers rise at 1.38 times the serials (i.e. take up 73%), because the other 27% is on other machines, such as 3's or 4's. Some serial and front left foot numbers of Nr. 4 machines could confirm or disprove that.

Even so, most likely explanation is that these foot numbers are sequential serial numbering from the casting finishing-shop.

More insight, still curious :-)

Another update/addition:

As Mr Polt pointed out, there's also a number on the carriage-frame. On the 1920 Underwood 5 also pictured above, this right-side of the carriage frame number is identical to the foot number. On my 1928 machine it's different - but that was at first-sight. On further looking at the numbers, it's actually very informative :)

On the 1924 machine the carriage number was by the way also identical to the foot number 2,461,255.

On the 1928 machine however the carriage number is 3,389,092. The foot number is 389,092 - i.e. the foot-number is the last 6 digits of the carriage number. Ergo, let's assume that the foot number in full should be read as 3,389,092 too.

On this still limited data, the theory would be that the carriage number is the same as the foot-number.

This also gives a theory on the reason for stamping these numbers. The numbers being 'hidden' indicates they are only for use by Underwood in manufacture. The visible serial-number is the one that's intended for unique identification of the machine by trade and customers.

If the number was only on the frame, it could for example have been to track some measurements on paper that were needed for later assembly (stamping costs money, would have needed a reason).

Now that the same numbers are on both frame and carriage, a plausible new theory is that they're simply for enabling (re-)matching carriage and machine-base. That would also make re-starting the numbers every year or indeed only stamping the last 6 digits not a problem (and saving a bit of money). (I.e. the purpose similar to the serials on K&E mahogany sliderules; serials rolling-over every decade or so was fine because they were created mainly to be able to re-match tongue and rule during manufacture.)

More data is indeed more insight and better theory on what and why - and still curious :-)