The rubber 'stopper' feet of Underwood 5 typewriters are almost always 'gone'. The rubber is generally hard and the weight of the machine has compressed the foot. This is bad, not just because the rubber does not dampen any noise anymore, but also because it means the machine probably now rests on a sharp metal 'pin' on the head of the bolt that is inside the rubber 'stopper'. So; best replace with new feet.

To make new feet for an Underwood 5; a simple plastic cylinder was made to take original, salvaged bolts taken from disintegrated Underwood 5 feet. These could have been 3D-printed in rubber (TPU), but in this case printed from rigid PLA and given a pocket to take 3 or 4 mm stick-on furniture felt. The felt was given a rubber-coating for anti-slip.

These foot-bolt inserts are turned from square stock and have a ~6.15 mm threaded stud for mounting on the machine. Re-using these bolts is a good thing, because this is today an uncommon screw-thread. It's almost the same as UNC 1/4" with 20 tpi, but not quite. With tolerances of manufacture, a modern quarter-inch UNC screw may fit the machine, but it's about 0.2 mm too wide. (Outer diameter of UNC 1/4" is 0.250" (obviously) and #14 diameter is 0.242".)

An Underwood 5 has American N 14-20 threaded holes for mounting the feet; this thread was removed from ASME standards already in the 1940s. This used to be a fairly common screw size as I've read. To add to the diversity of threads, it exists both as 14-20 and 14-24 (i.e. 24 threads per inch). In either case, today nearly unobtainable.

So it's a good thing to re-use the original bolt-inserts of the old, original feet if possible.

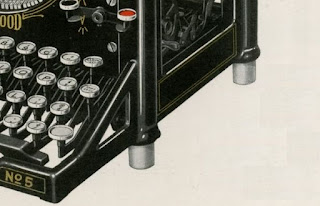

Sizing of the feet themselves is a guess - estimating from the remains of the old feet, chose a diameter of 20 mm (25/32 inch ?). On photographic evidence of the 1920s the feet do look similarly thin and cylindrical, but not quite as thin as all that.

Giving it some thought, a diameter of 7/8" is more likely. As we're 'anoraking' anyways and these being easily printed; manufactured a new set with the larger 7/8" diameter.

These look a bit more substantial - and less ridiculously flimsy on the machine. Now the Underwood 5 typewriter with new cylindrical feet that are probably similar to the original when-new feet.

It remains to be seen how well these feet hold up over the years. The PLA material is very strong at room-temperatures, but will weaken when hot. At temperatures over 60 degrees C they will probably slowly 'collapse' and be squished (actually, just like the original feet did! Very authentic :-). That's where the felt-pads come in, they will prevent the bolts from protruding and scratching the table.

For now, this common Underwood is on a stable footing again. And with the cushioning felt, also much quieter on the table! :)