It is again surprising how much an old typewriter benefits from simply cleaning it. This old Underwood 3-bank Portable looked a right project, with a brownish hue of rust all over the machine.

Much of the rust turned out to be superficial, although some areas are rather pitted and patches have lost all nickel. With basic washing, polishing (Brasso) and the occasional use of fine steel wool, all surfaces came back to a shine. Areas with pitting and plating loss were given the aluminium-treatment. Rubbing with a tightly crumpled wad of aluminium foil will abrade aluminium into the rougher rust areas - this makes nickel-loss much less obvious.

Cleaning also clarified the serial number. Turns out I misread the number and it is a 1926 machine, not a '23. The leading '1' is easily confused for an edge of the stamping tool or missed entirely. My guess is that this is the reason for several early 3-banks with late-model features in The Database.

The bell and margins-stops that were heavily tarnished and pitted have become quite presentable. Even the drawband was given a wash. This sounds somewhat over-the-top perhaps, but the reason was that it was starting to fray at the edge at one spot. To be able to tamp-down the loose threads with latex textile glue, the band was removed and first washed to get rid of grime and dirt. It still is grey, but now the latex had a chance to connect with the fabric instead of with dirt only.

The wayward 'N' keytop and the left shift-keytop were also straightened (Underwood did not make these rings easy to get off, by the way - limpets, the lot of them!...).

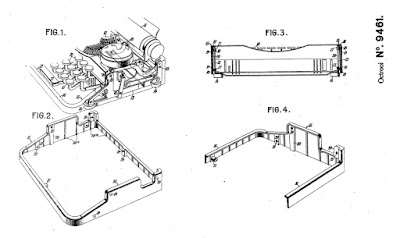

There is still the whole typewriter to be adjusted and internals to be cleaned - nothing lines up properly yet. The ribbon-advance is easily accessible and was cleaned thoroughly, the ratchets move freely again. The font panel is by the way fixed with 5 screws (green ring), the rest of the screws are the mounting of the ribbon-reverse (forks with linking-bar).

The botched screw is evidence that somebody repaired, or at least tinkered with the typewriter in the past. Similarly that missing left paper-finger - this does not just slide off the carriage, but a screw has to be removed for this to come off!

Now to look for a way to give it again a left paper-finger - probably will make an attempt at re-manufacturing the part (this is an unlikely part for anyone have a spare one lying about). And more cleaning and adjusting: it's really a very nice little barn-find project-machine :-)

No comments:

Post a Comment