Friday, December 20, 2024

New spacebar for an Oliver 3 typewriter

Wednesday, December 11, 2024

American National 14-20 screw thread and 7/8th Inch

Giving it some thought, a diameter of 7/8" is more likely. As we're 'anoraking' anyways and these being easily printed; manufactured a new set with the larger 7/8" diameter.

Saturday, November 23, 2024

What are front left foot numbers on an Underwood 5 ?

The Underwood 5 typewriter has the serial number stamped on the frame-top near the right spool. The number itself is generally followed by a type-designation, so the pattern is xxxxxx-5 for a regular Nr. 5. The number is on a flat, machined surface and linear - feasible to stamp with an automatic numbering stamp.

Here the Underwood 5 serial number on a 1920 machine (type "5" on the extra face/facet):

Probably on every Underwood 5 (or 4, 3, 46T etc.) there is another number stamped into the frame. This number is stamped in the flat, machined surface under the front left foot. The digits are arranged around the screw-hole for the foot, to fit in the area. This makes it less likely to have been an automatically incrementing numbering stamp, but more likely hand-stamped.

Here the extra "front left foot number" on that same 1920 machine:

Another example; here the front-left foot and the top-right of the frame in one picture:

(Yes, it's in pieces. This Underwood was completely broken; dropped/tumbled onto a concrete floor from some height. The cast iron frame was shattered and all panels crumpled. The wreck is being salvaged for parts to fix other machines.)

From these and a few other machines, e.g. on The Database or mentioned on the net, some serial numbers with their front left foot numbers can be found.

serial number year front left foot number

475,051 1912 541,824

734,809 1914 874,286

1,411,885 1920 1,812,200

1,872,237 1924 2,461,255

2,446,801 1928 389,092

3,677,613 1930 111,938 (46T)

Can't help but wonder; what are these numbers?

They don't look to contain dates. They do not correlate with the machine serial numbers. Come to that; are they actually serialised, another serial number range for the foundry? They are not all incrementing.

Are they perhaps job-numbers; per order of a batch of finished-frames so that several machines within a range of serial numbers will have the same front left foot number?

Could the "24" on that 1924 machine be a year prefix to a job-number? But that wouldn't explain the "18" on the 1920 machine (late 1920, November-ish).

Update!:

If the last two numbers are ignored, the range is actually nicely incrementing. That could be reasoned e.g. when the '28 and '30 numbers are after a change in the method. (E.g. restart at zero every year), after the number started to become cumbersome to stamp in the mid 1920s. Then the serial and left foot numbers correlate very well - they have a linear relation:

Left foot numbers rise 1.38 times the speed of serials. That could indicate that not all casting numbers are for machine frames - about 73% of stamped parts would be for Underwood 5 typewriter frames. The practice of stamping the casings would have started around Underwood 5 machine serial number 100,000 - about 1906. (Could be checked, will a pre-1906 machine have a front left foot number?)

Could be that for the Underwood 5 the left foot numbers rise at 1.38 times the serials (i.e. take up 73%), because the other 27% is on other machines, such as 3's or 4's. Some serial and front left foot numbers of Nr. 4 machines could confirm or disprove that.

Even so, most likely explanation is that these foot numbers are sequential serial numbering from the casting finishing-shop.

More insight, still curious :-)

Another update/addition:

As Mr Polt pointed out, there's also a number on the carriage-frame. On the 1920 Underwood 5 also pictured above, this right-side of the carriage frame number is identical to the foot number. On my 1928 machine it's different - but that was at first-sight. On further looking at the numbers, it's actually very informative :)

On the 1924 machine the carriage number was by the way also identical to the foot number 2,461,255.

On the 1928 machine however the carriage number is 3,389,092. The foot number is 389,092 - i.e. the foot-number is the last 6 digits of the carriage number. Ergo, let's assume that the foot number in full should be read as 3,389,092 too.

On this still limited data, the theory would be that the carriage number is the same as the foot-number.

This also gives a theory on the reason for stamping these numbers. The numbers being 'hidden' indicates they are only for use by Underwood in manufacture. The visible serial-number is the one that's intended for unique identification of the machine by trade and customers.

If the number was only on the frame, it could for example have been to track some measurements on paper that were needed for later assembly (stamping costs money, would have needed a reason).

Now that the same numbers are on both frame and carriage, a plausible new theory is that they're simply for enabling (re-)matching carriage and machine-base. That would also make re-starting the numbers every year or indeed only stamping the last 6 digits not a problem (and saving a bit of money). (I.e. the purpose similar to the serials on K&E mahogany sliderules; serials rolling-over every decade or so was fine because they were created mainly to be able to re-match tongue and rule during manufacture.)

More data is indeed more insight and better theory on what and why - and still curious :-)

Sunday, November 17, 2024

Pencil leads and fractions

Two surprise thrift store finds.

The first is a Koh-I-Noor box of red pencil leads. Well, a box with one red pencil lead - it is however still in one piece! The card sleeve-box with wooden frame protected this sole remaining lead well, probably for more than 80 years.

Now, the label could have simply stated that it contains six (6) leads, or perhaps to be fancy it could have stated; 'half a dozen'. No, this label goes even fancier in fractional obfuscation - it contains 1/24 gross! Nice :-)

The second find also has a fractional aspect. This is a Pelikan tube with HB leads of ~1.18 mm diameter. Great to find these on the cheap, because that is the size needed for many vintage mechanical pencils. The diameter of the lead for vintage mechanical pencils (Yard-O-Led) actually got started as 3/64 Inch. The metric 1.18 mm is a decent approximation for that :)

And it's the size for my mechanical pencil, now again well-stocked for leads :-)

Thursday, November 14, 2024

How to operate the Dalton Adding Machine

The Dalton Adding Machine can add, but also subtract, multiply and more. How to operate it is not always immediately obvious today from just looking at the machine. Below will show how to do some of these operations on a Dalton.

The machine used here is a very basic Super Series machine, i.e. a 2nd generation Dalton 10-key adding machine as was introduced in 1921. The pre-1921 first-generation Dalton machines however work much the same way, just that some function keys are in different locations. Early machines also have slightly different method of e.g. how to perform a total or sub-total.

More advanced Super Series machines have more features and are capable of more functions:

Note by the way that the paper should be mounted to feed from the bottom of the roll.

Clearing the machine

Before any operation, make sure the machine is clear, i.e. is at zero. This is done by doing a total; press-in the total-key, it will latch in the pressed-in position. Then pull the lever forward all the way and let it return. An asterisk printed on the paper tape will confirm that the machine is empty at the start of a calculation. (Or will print a value if the machine was not empty, of course.)

If the total-key is blocked, first do an "empty-stroke". That is, one stroke of the lever with an 'empty' keyboard. This will enable the total-key. The keyboard-clear indicator is the oblong window just behind the digit-keys; if this shows 'blank' (no dots) then the keyboard is 'empty'. A total or sub-total always has to be preceded by an empty-stroke.

(Apart from the keyboard-clear indicator, control-keys on the Dalton are helpfully labeled with their function.)

Adding

To then start an addition, enter every value as is done on a modern calculator; so $ 12.50 is entered as 1, 2, 5 and 0 in that order. The keyboard-clear indicator will show the number of digits entered with coloured dots.

To add this value into the register (or accumulator) of the machine, pull the lever forward all the way and let it return.

Repeat for every value to be added. The keyboard will be cleared automatically at the end of a stroke.

To get the total, first do one empty stroke, i.e. a pull of the lever without any number entered (the keyboard-clear indicator blank). Then push in the total-key and do a stroke. The total will print with an asterisk next to it and the machine register is cleared to zero. (On most Dalton machines, the totals are printed in red. This most-basic machine however does not have the bi-color function.)

The total sum of the values 12.50, 37.97 and 6.95 is thus printed as 57.42 on the paper. (This machine has a wider space between the 2nd and 3rd column numbers to make reading of dollar and cent values easier - this can however vary per machine.)

A sub-total prints the value of the register with an 'S' in the right margin, but does not re-set the register to zero. Example below with a sub-total after adding 123, 456 and 789, and then a total after adding 321, 654 and 987.

Above shown on a bi-color capable machine, with the total and sub-total lines printed in red.

When e.g. the total-key or another function key is pressed in error, pressing the release-key will release it.

Pressing down the large correction-key will completely clear the keyboard entry. Pressing the backspace-key will remove one, right-most digit.

Multiplying (from right)

Supposing a 21% surcharge (VAT, carriage, etc) needs to be added to the $ 57.42 value calculated above. Then 57.42 needs to be multiplied by 1.21.

Enter 5742 on the keyboard and push down and to the back the multiply-key to latch it in the down-position. (The multiply-key prevents the keyboard being cleared at the end of a stroke. That is all it does.)

With one lever-stroke enter the right-most digit of 121. Then enter a zero on the keyboard, this will change the number entered to 57420, and pull the lever twice to enter the next digit of 121. Add another zero (making 574200) and one stroke to enter third digit of 121.

Then press the multiply-key once to release it, press down the correction-key to empty the keyboard and do an empty-stroke followed by a taking a total.

To point-off: the multiplicand and multiplier both have 2 decimals, so the result will have 2+2 is 4 decimals. The result of 694782 should thus be read as 69.4782. This gives that $ 57.42 with a 21% surcharge added as $ 69.48 when rounded to dollars and cents.

Dividing (multiplication from left)

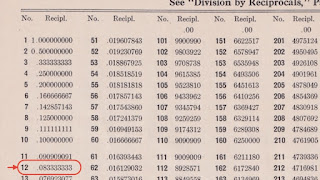

On the Dalton, dividing is done by multiplication with the reciprocal of the divisor. I.e. dividing by 5 would be a multiplication by 0.2 (1/5). A table of reciprocals was provided with the machine, a larger table of reciprocals was available separately from the company for numbers of 1 to 10,000.

Supposing the amount of $ 69.48 needs to be paid in 12 instalments, the value needs to be divided by 12. Looking this up in the table, the reciprocal of 12 is 0.083333.

To multiply 69.48 with 0.083333, the value of 6948 is entered and padded with zeroes to fill the buffer. Then the backspace-key is pressed once. I.e. on an 8-column machine, the keyboard-clear indicator will show 7 digits are entered.

Then multiply from the left, so start with 8 strokes of the lever for the left-most digit. Press the backspace-key once and enter the next digit with 3 strokes. Repeat until the keyboard is empty, or enough digits for the precision needed have been done (e.g. 5 digits to get a fair 4-digit answer).

Then draw the total - showing the answer as 57899973. The answer is approached from below with this method, so rounding should be up. The answer is then $ 5.79 when rounded to two decimals for dollars and cents.

Doing a quick multiplication by 12 of 579 from the right gives 6948 confirming this is the exact, correct answer. (Otherwise, there would be a correction for the final instalment to make up for any fractional mismatch.)

Subtracting

Sunday, November 3, 2024

Finishing the refurbishment of a Dalton Adding Machine

The surplus wreck Dalton is now refurbished, quite the transformation from what it was :)

The machine was cleaned inside and outside. The brightwork was de-rusted and all outer parts re-painted. With a few small repairs to its mechanism too, it can now be properly called: refurbished.

To complete the refurbishment (or restoration), the front and rear panels were re-painted and new gold decals applied. The number-keys were replaced, and as final-step fitted with new rubber feet.

Panels with decals

After some hesitation, also the front and rear panels were stripped down to bare metal.

These panels have the gold lettering with the Dalton logo. The front decal had been severely degraded, but the rear had fared a bit better. Both in the end were removed to re-paint the panels in gloss black.

There is some variation in the exact shape of the Dalton script logo on machines. Suppliers of these decals maybe made their own cliches for this - or the Dalton company was simply 'vague' on an exact script.

Just picked one design of the mid 1920s and created reproduction decals. The lettering on this front decal should have been a tad smaller, and the second-line should've been slightly smaller than the first. But as Dalton varied their decals too, deemed good-enough.

Decals printed on waterslide transfer paper as previous projects, filled with gold-paint and then applied. More softening-liquid and a lacquer clear-coat will make the film less visible. Viewed from the front it is already quite passable.

New number-keys

The wreck had ended up with the worn and damaged keys. To complete the refurbishment, a new set of number-keys were manufactured. Copies of the designs were modelled in CAD (FreeCAD).

These designs were then 3D printed in FDM with a 0.4 mm nozzle, so fairly rough and fast prints - printing with a fine nozzle or printing in resin would create much finer detail. Even though these are relatively 'cheap-n-cheerful' replacement keys, they do look the part already.

Visible layering at the top-surface was of course sanded smooth and the keys were painted off-white. They were already printed in white PLA material, but an extra layer or two of paint makes them more opaque and also smoothens any remaining layering. The lettering was filled with red and black paint.

There are some minor mistakes in these keys so they may yet be replaced with slightly better copies, but for now they'll do.

(The 'clear-signal' indicator just above the keyboard here shows that 4 digits have been entered. This indicator was also given a new, laser-printed legend and the yellowed celluloid window replaced with a clear acrylic reproduction.)

New feet

From images in contemporary publications, these Dalton Super Model machines would have come with rubber feet.

These feet were a little larger than the metal 'stub' and look as if less than half their diameter in height. The 'stub' at ~23 mm diameter, the factory-fitted feet were likely one inch diameter and, say, perhaps 7/16" in height.

Online there's a wide range of rubber feet - a set of 25 mm x 10 mm feet were sourced and screwed to the machine. It sits very solid, no skidding! It also transmits the sound very well into a table; definitely louder than the makeshift cork feet. Dalton's are loud machines. (Cork could've been a good choice for feet after all!)

Refurbished Dalton Adding Machine

This is the simplest, lowest cost 100-dollar 'Special' of the Super Model range. As such it is a fairly common and perhaps not very interesting machine. Indeed, these Daltons are today not very desirable or valuable; it's debatable if this was 'worth the effort'

Nevertheless it's historic digital-technology and an example of the state of office automation of 100 years ago. More than a photograph or document, it can be experienced and operated. As such it perhaps is worth preserving - plus of course that it simply was an enjoyable project!

(As always; after completing the process, then there is the insight in how it should have been done. A next Dalton refurbishment will be done better ;-)

Friday, November 1, 2024

Good advice for the Hammond typewriter

When delivered new in the 1910s, a Hammond typewriter would have had a 'Special Notice' card placed on its keyboard-card tray. It contains some useful advice for typing on the Hammond and especially on where to oil it occasionally (and where not).

From a couple of pictures found online of miraculously surviving specimens of this card, a quick re-creation was made and printed on heavy, ivory paper. Dimensions approximately 23 by 5 cm or about 9 by 2 inch:

Unlikely to remain on the machine, but good advice nonetheless :-)

Saturday, October 26, 2024

Folding Corona - as simple as closing a book

(Full-page advertisement from the February 1920 issue of Popular Science, page 153.)

Or is it.

It's intuitive and folding over works. Just like closing a book. Unlike a book however, the Corona should ideally have its carriage locked in the correct position and its shift locked.

The many images of folded Corona 3 typewriters, both online and in print, suggest that often the shift is not locked - and the rear folding-beams pop back up.

When the shift is locked however, the Corona 3 typewriter folds very neatly flat.

The locks also reduce strain on the machine when it's in the carrying-case.

Folding Corona - almost as simple as closing a book ;-)