To start the re-assembly of the Comptometer, they newly-lacquered key-plate is mounted back onto the mechanism. Before doing that, the red controlled-key button must be mounted (insert stem from underneath through hole and press the button on the stem).

Also the name-plate has to be mounted first; this is screwed not onto the key-plate, but it is screwed into large washers that also serve to hold the cork lining in place. In practice with old machines, these washers will be 'glued' onto the cork and the plate could perhaps be screwed of safely - however there is also a risk the large washer will drop free and deep into the mechanism (and then no way to re-mount the name-plate without a full disassembly and taking off all keys!).

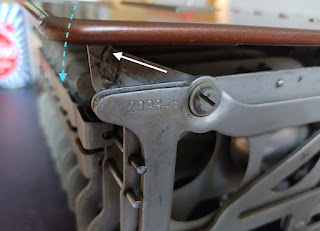

The key-plate having been prepared, the front of the plate is hooked under the two tabs at either side of the carry-suppression levers.

At the rear of the mechanism on the sideframes, there are two tabs that can swivel up. With these 'clicked' out of their position and angled up at about 30 to 45 degrees, these swivel-tabs have fingers that will catch under the rim of the key-plate as it is brought/rotated down onto the mechanism.

With a 'click', the key-plate will sit flat on the mechanism and all the little tabs should protrude evenly through all the little aligning slots of the key-plate. With the four screws (on an 8-column machine) right behind the 9-keys slots the key-plate is firmly fixed on the mechanism.

Then the keys can be re-mounted - one column at a time. The order does not matter too much, unless the holding-levers and springs on the bottom of the machine were completely taken out; then it is best to work from high (left) to lower (right) columns because a lower column lever-leg is placed on top of the lever-leg of its higher neighbour.

Starting with the 9-key and working down turned out to be the practical way to re-fix the keys. Insert from the top, wiggle gently and the curved end of the key-stem will show up near the V-shaped lever that has to catch it (circle).

To make the curved end drop into the hole of the V-shaped lever, it can be tilted by unhooking one leg. Then re-placed and the torsion-spring again locked under its tab (arrows). The 9-keys are trickiest to get proper access to for this manoeuvre and small pliers may be needed to get at/tilt the lever, but otherwise its fairly straightforward. It just needs to be done 72 times (on an 8-column machine).

No comments:

Post a Comment