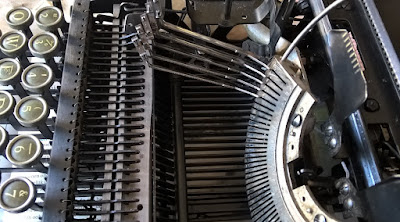

The typebars of the Synela portable typewriter were very dirty. The slots in the segment also looked filled with dirt. To thoroughly clean these and make everything move smoothly again, the typebars were taken out of the machine. By pulling out the pivot-rod, the typebars can be slid out of the slots and manoeuvred out of the machine.

The typebars were heavily tarnished (black), but the bearing-surfaces also turned out to be covered in oil. The segment slots were filled with black 'deposits' and equally well oiled. This may have been old oil, but perhaps it was recent oil (or WD40...) - quite plausible that the segment was 'soaked' about 5 months ago to make the typebars move again when putting it on Etsy as 'working'.

Keeping a segment oiled is generally a bad idea. It can give temporary relief and make everything move freely, but will attract dust and dirt and over years can harden to completely clog a machine (especially WD40 will harden). Creeping oil or WD40 can be excellent for freeing things up, but really has to be washed-out thoroughly afterwards. The oil in the slots confirmed that this machine really needed taking apart for cleaning.

The typebars are numbered, but the pull-rods that connect them to the intermediate bell-cranks are not. These 44 rods are also all differently shaped and need to go back in their correct position. To keep track of these, all were given a numbered tag the moment they were taken out of the machine.

The segment had to be cleaned in-place on the machine, as its screws were impossible to loosen without risking damage. Rinsing with white spirit (i.e. petrol or gasoline, but without all the additives) solved the oil, but did not do anything against the dirt. Thorough scrubbing and rubbing in the slots with wooden skewers and thick card was needed to get rid of (most of) the black 'lining' inside the slots.

Also the tarnishing of the typebars could only be removed by vigorous polishing (Brasso!). After cleaning they still have some black corrosion (?), but at least the bearing surfaces are mostly clean and smooth again.

The typebars then all lined up and ready to be put back into a clean segment. They are numbered from 1 to 44, but also on this machine there is a small numbering hick-up as is oddly common on typewriters. On this one there is no 35 and there are two 34 typebars. Starting at typebar 1 and pushing in the pivot-rod further as typebars and rods are added, all the typebars are placed back in the machine and hooked-up with the bell-crank.

No comments:

Post a Comment